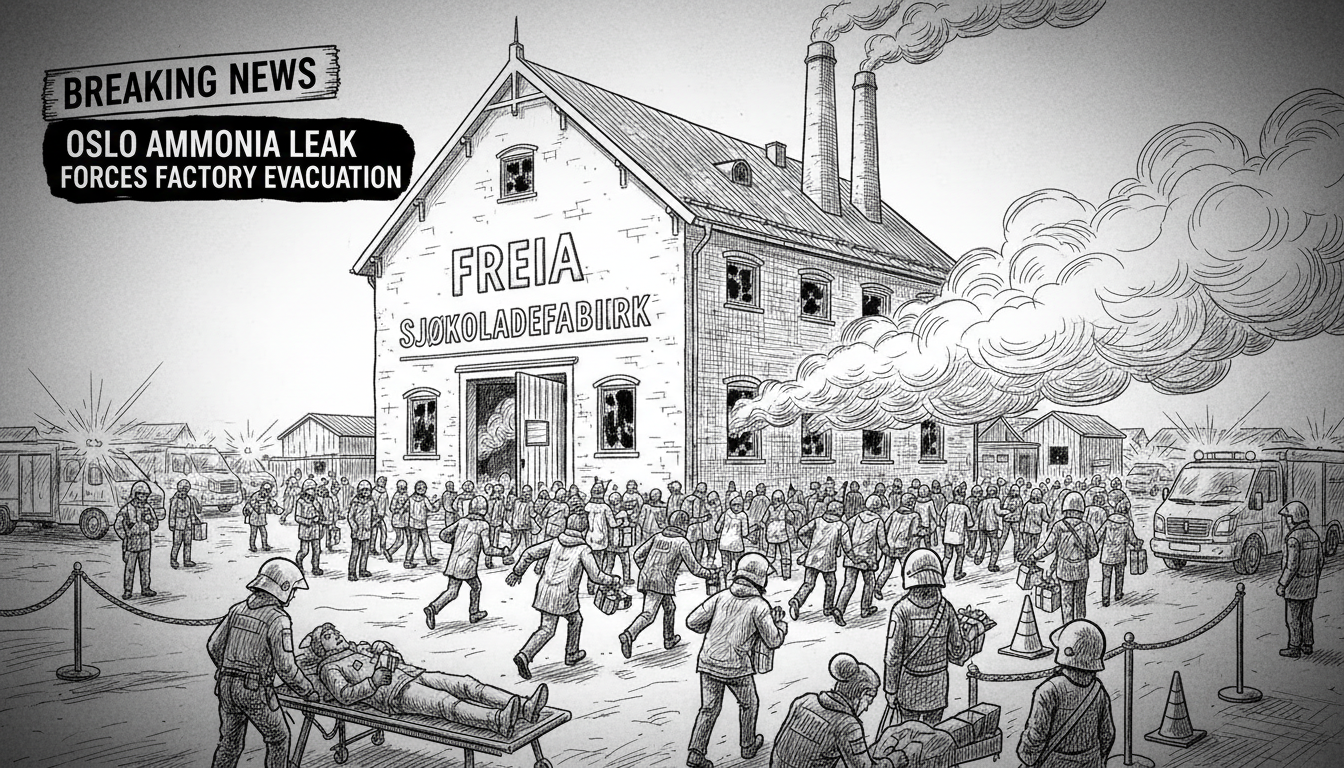

Emergency services evacuated approximately 150 people from a Christmas party at a chocolate factory in central Oslo following an ammonia leak. The incident occurred at the Freia facility on Rodeløkka, prompting a major response from police and fire departments.

Operations manager Alexander Østerhaug confirmed two individuals were exposed to ammonia gas but received medical clearance without requiring further treatment. Police established security perimeters around the factory complex while urging nearby residents to avoid the area.

Fire department commander Tim Angell reported seven emergency units responded to assess the leak's severity. Officials confirmed the ammonia release occurred inside the factory building itself. They determined no additional evacuations beyond the immediate facility were necessary.

Mondelez spokesperson Øyvind Olufsen acknowledged the incident in a written statement. The company representative confirmed ammonia alarms activated and buildings were evacuated. Olufsen deferred further commentary to emergency services managing the situation.

This industrial incident highlights Norway's ongoing industrial safety challenges despite the country's reputation for strict workplace regulations. The Freia factory sits in a mixed-use neighborhood where residential and industrial zones intersect. Such proximity creates complex emergency response scenarios for Oslo authorities.

Norway's chemical safety regulations require industrial facilities to maintain comprehensive emergency protocols. The swift evacuation of 150 people suggests these procedures functioned as intended. The ammonia leak's containment to the factory interior prevented broader community exposure.

Industrial accidents in urban centers raise important questions about zoning policies in Norwegian cities. As Oslo continues densification efforts, balancing industrial operations with residential safety remains challenging. This incident will likely prompt renewed discussions about industrial safety standards in mixed-use neighborhoods.

The factory's location near central Oslo transportation hubs added complexity to the emergency response. Police cordons affected local traffic patterns during the evening hours. Such disruptions demonstrate how industrial incidents in dense urban areas create ripple effects beyond immediate safety concerns.

Norwegian workplace safety authorities will certainly investigate the ammonia leak's root causes. Previous industrial incidents have led to tightened regulations and increased inspection frequencies. This pattern suggests regulatory responses often follow such events despite Norway's generally strong safety record.

Chemical safety protocols at food processing facilities require particular attention because many substances serve dual purposes. Ammonia functions as both refrigerant and potential hazard in chocolate production. This dual use necessitates robust safety systems and regular staff training.

The incident's timing during holiday celebrations adds social dimension to the industrial safety discussion. Workplace parties represent important cultural traditions in Norwegian companies. Ensuring safety during such gatherings requires additional planning and coordination.

Emergency services demonstrated effective inter-agency cooperation during this incident. Police, fire, and medical responders coordinated their efforts efficiently. This coordination reflects Norway's integrated emergency response system developed through regular training exercises.

Factory operators now face the dual challenge of investigating the leak's cause while maintaining production schedules. Such disruptions can affect supply chains for Norway's iconic chocolate products. The company must balance transparency about the incident with protecting commercial interests.